42 nickel aluminum phase diagram

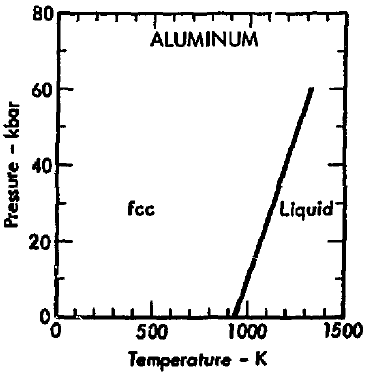

Phase Diagrams • Indicate phases as function of T, Co, and P. • For this course:-binary systems: just 2 components.-independent variables: T and Co (P = 1 atm is almost always used). • Phase Diagram for Cu-Ni system Adapted from Fig. 9.3(a), Callister 7e. (Fig. 9.3(a) is adapted from Phase Diagrams of Binary Nickel Alloys , P. Nash The work finds application in the design of multi-component nickel and aluminum based alloys that are used in many technologies as structural materials. The experimental results of the study will provide the needed data for phase diagram calculations using CALPHAD methodology that is far more efficient than the currently available techniques.

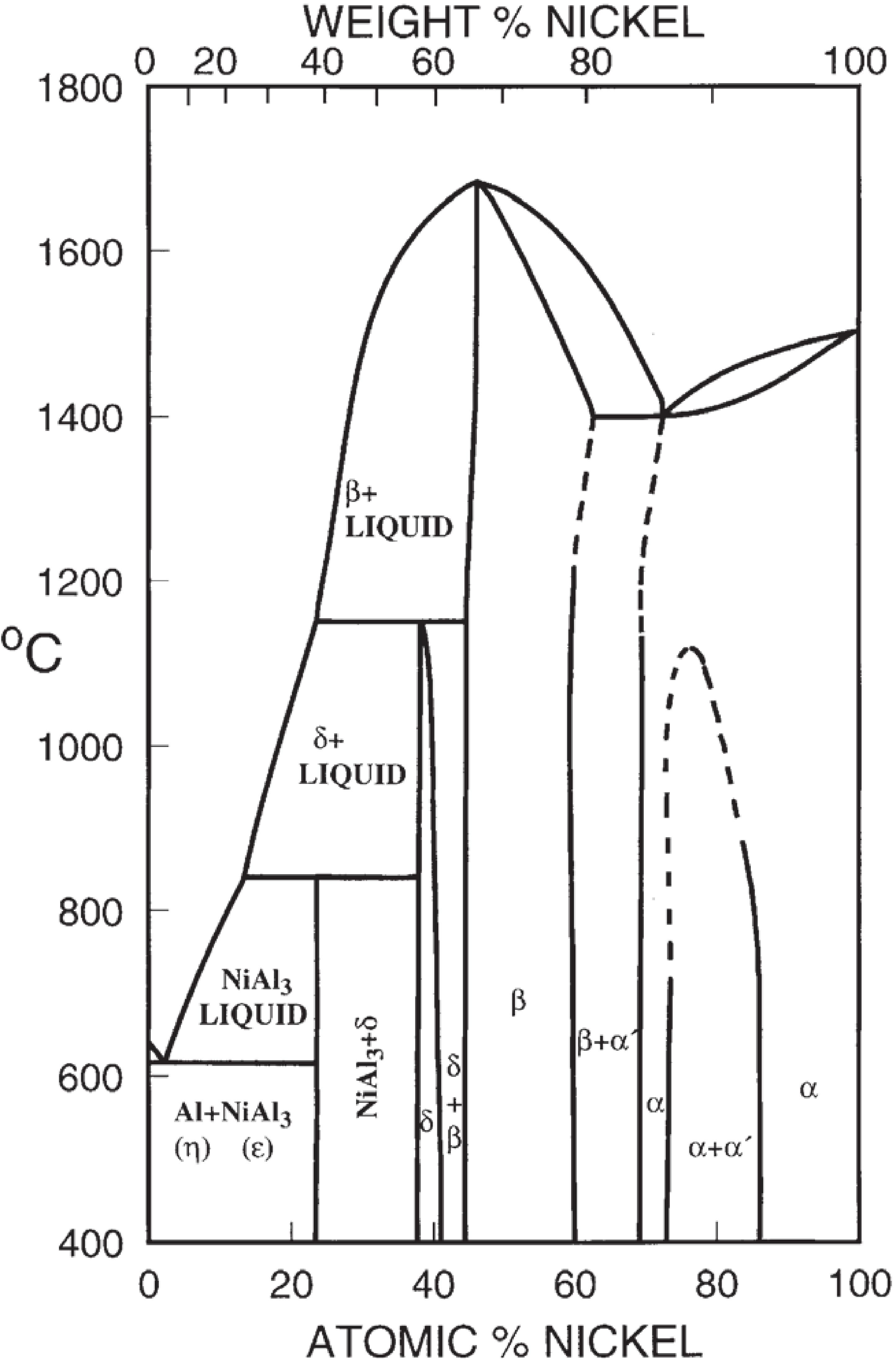

Al-Ni (Aluminum-Nickel)H. OkamotoThe Al-Ni phase diagram in [Massalski2] was adoptedfrom [1991Nas]. Solid lines in Fig. 1 show the Al-Ni phasediagram ...

Nickel aluminum phase diagram

by DF SUSAN · 2000 · Cited by 55 — Nickel-aluminum intermetallic alloys based on NiAl or Ni3Al have shown good ... coating composition and dictates, through the phase diagram, ... forms with aluminum a series of nickel aluminides; one of them is Al 3 Ni ( in the diagram). Aluminum forms a eutectic with Al 3 Ni at 6.1 wt% nickel. The melting point of the Al-Al 3 Ni eutectic is 640 C and the volume of the Al 3 Ni phase in the eutectic is relatively large (about 9.7 wt%). Furthermore, the Al 3 Ni eutectic phase Phase Diagrams • Indicate phases as function of T, Co, and P. • For this course:-binary systems: just 2 components.-independent variables: T and Co (P = 1 atm is almost always used). • Phase Diagram for Cu-Ni system Adapted from Fig. 9.3(a), Callister 7e. (Fig. 9.3(a) is adapted from Phase Diagrams of Binary Nickel Alloys , P. Nash

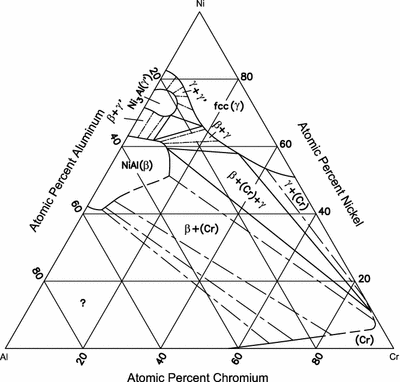

Nickel aluminum phase diagram. Phase equilibria in the Ni-Al-Cr system at 1150°C were investigated by using annealed ternary alloys and diffusion couples. The phase constitutions, microstructures, and tie-lines were determined by conventional techniques, including X-ray diffraction, scanning electron microscopy and electron probe microanalysis. The solubility limits of Cr was found to be about 9at.% in the γ' and 17at ... Superalloys can be based on iron, cobalt or nickel, the latter being best suited for aeroengine applications. The essential solutes in nickel based superalloys are aluminum and/or titanium, with a total concentration which is typically less than 10 atomic percent. This generates a two-phase equilibrium microstructure, consisting of gamma ( γ ... aration techniques for aluminum metallographic samples. Phase diagrams and identification of constituents, important to the interpretation of struc tures, are covered in Ref 2 and 3. Many of the changes that become apparent with the examination of aluminum macrostructure and microstructure occur simultaneously with Aluminium increases strength, seawater and scaling resistance. Beryllium has the strongest effect on mechanical properties after age-hardening. The solubility of carbon in nickel (max. 0.18%) is severely reduced as copper content increases - it is about 0.01% with a copper content of 90%. Carbon is not detrimental in Cu-Ni alloys.

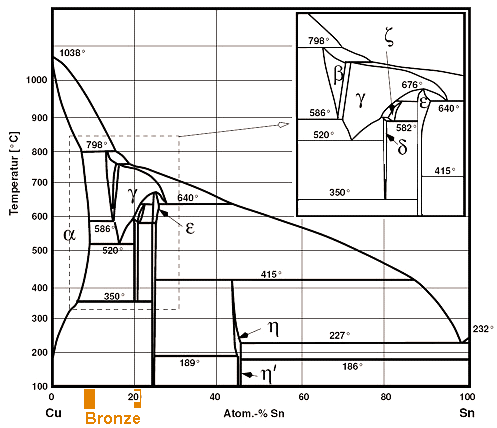

The aluminium bronze and nickel aluminium bronze equilibrium phase diagram s shown in Figures 34 and 35 can appear rather complicated with a number of microstructural phase s possible. In the binary system of copper and aluminium, Figure 34, for up to approximately 9% aluminium, the equilibrium metal structure is a single (alpha) phase. The Nickel-Aluminum System Nickel Oxide~AluminumOxude System ... Nickel-Nickel Oxide-Spinel Phase Field 249 Iron-Wustite-SpinelPhase Field 250 ... The Fe-O phase diagram (35,36).., Variation of wustite composition with 0z pressure and temperature. Fe-Al Sy~(8),. A preliminary study of the region of stability of the Ni 5 Al 3 phase in the nickel-aluminum binary phase diagram has been made using powder x-ray diffraction and optical and electron microscopy. Ni 5 Al 3 is stable below about 700°C. The variation of the lattice parameters and morphology of the Ni 5 Al 3 precipitates formed in 63 and 70 at.% nickel-aluminum alloys as functions of the ... The γ-phase is a solid solution with a cubic-F lattice and a random distribution of the different species of atoms. Cubic-F is short for face-centred cubic. By contrast, γ' has a cubic-P (primitive cubic) lattice in which the nickel atoms are at the face-centres and the aluminium or titanium atoms at the cube corners.

Transcribed image text: Consider the aluminum nickel (AI-Ni) phase diagram. For this phase diagram: Label the two-phase regions in the phase diagram. Determine the Coordinates of the composition and temperature of the invariants reactions. Write the equations for the three-phase invariant reactions and name them Make sketch of the ... These proceedings collect papers presented at a symposium on alloy phase diagrams. Topics include: Crystal phase transformations; order-disorder transformations; crystal lattices; metallic glasses; metastable states; solubility; binary alloy systems; and alloys of iron, tantalum, silicon, aluminum, germanium, palladium, copper, and nickel. at the left of the diagram where the alloy is in solid solution (phase ), a face centred cubic structure like copper. For the typical alloy CuBe1.9 (1.8 to 2% of beryllium) the alloy is in the phase between 720°C and 860°C. For industrial purposes the solution heat treatment is done between 750° and 800°C. By rapidly cooling the Aluminium matrix composites were prepared by High Velocity OxyFuel spraying of nickel powder onto the aluminium sheet's surface followed by annealing in a range of temperatures 600-630 degrees C ...

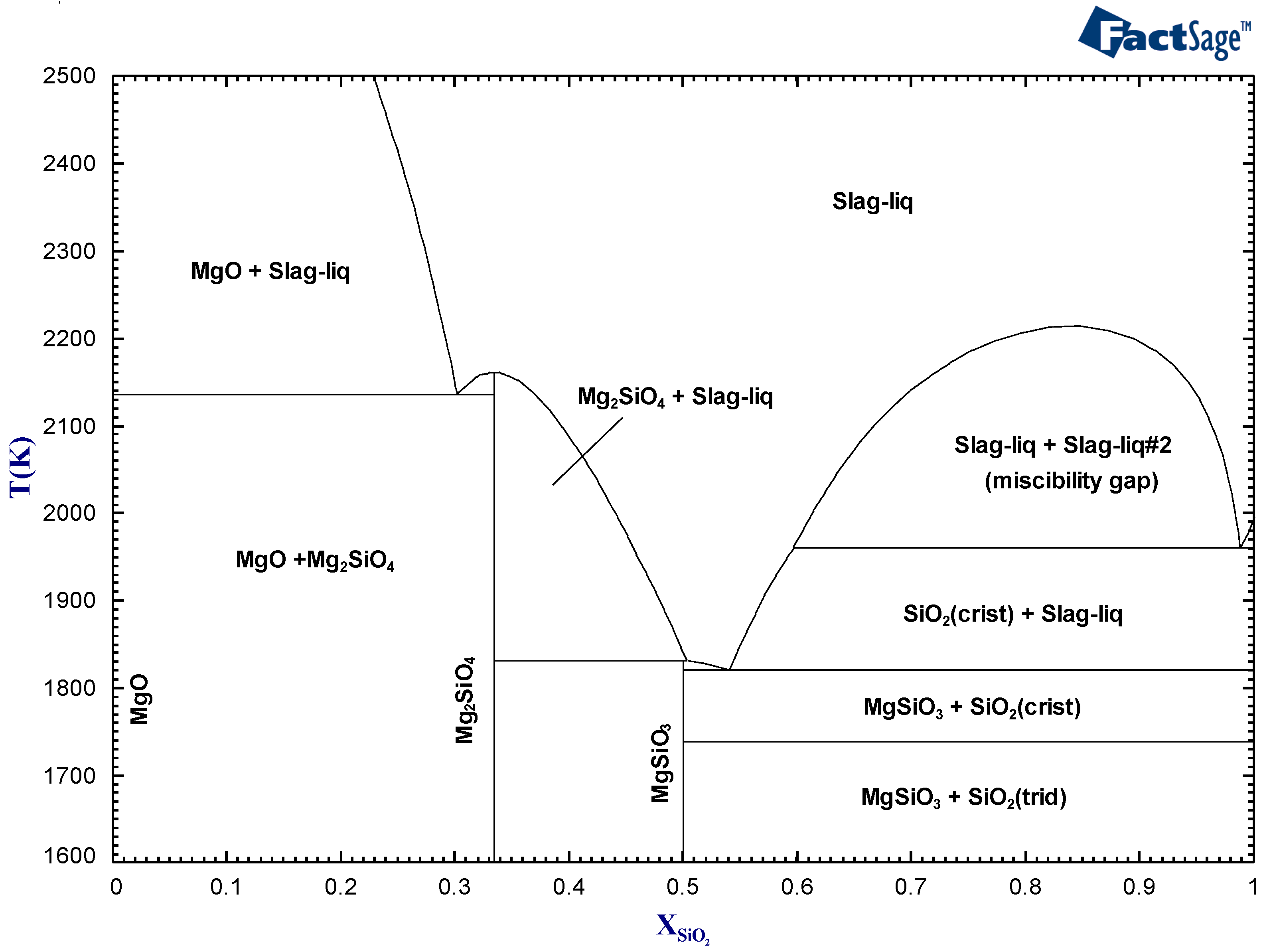

Atomic percent nickel Phase diagram for Gold-Nickel showing complete solid solubility above about 800oC and below about 950oC. The miscibility gap at low temperatures can be understood with a regular solution ... Phase diagram for light metals Aluminum-Lithium. There are five phases illustrated; however the BCC Lithium end-member phase shows ...

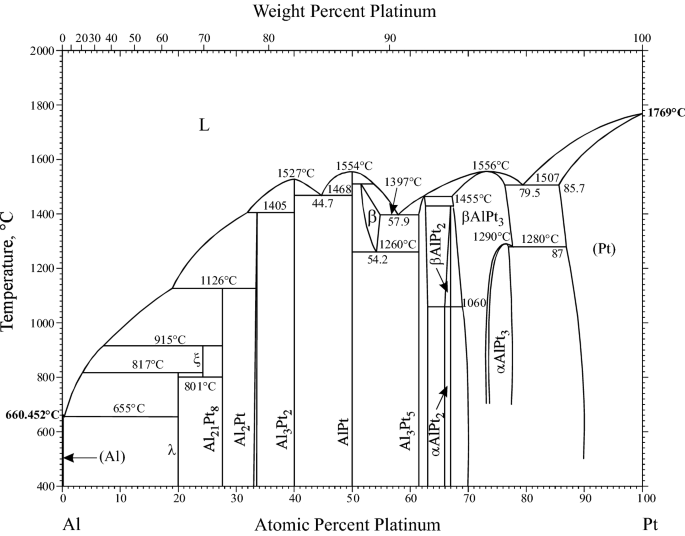

Supplemental Literature Review Of Binary Phase Diagrams Al Pt As U C Li C Mg Cd Nd Co Ta Fe Re Ga Y La Ni O V P Si And Re Zr Springerlink

The Properties of Electroless Nickel 113 Fig. 4.2-Nickel-boron phase diagram (1). Careful analysis (7) of X-ray diffraction patterns of electrodeposits containing 12 to 13 percent P has shown, however, that even high-alloy deposits.may contain small regions that are microcrystalline.

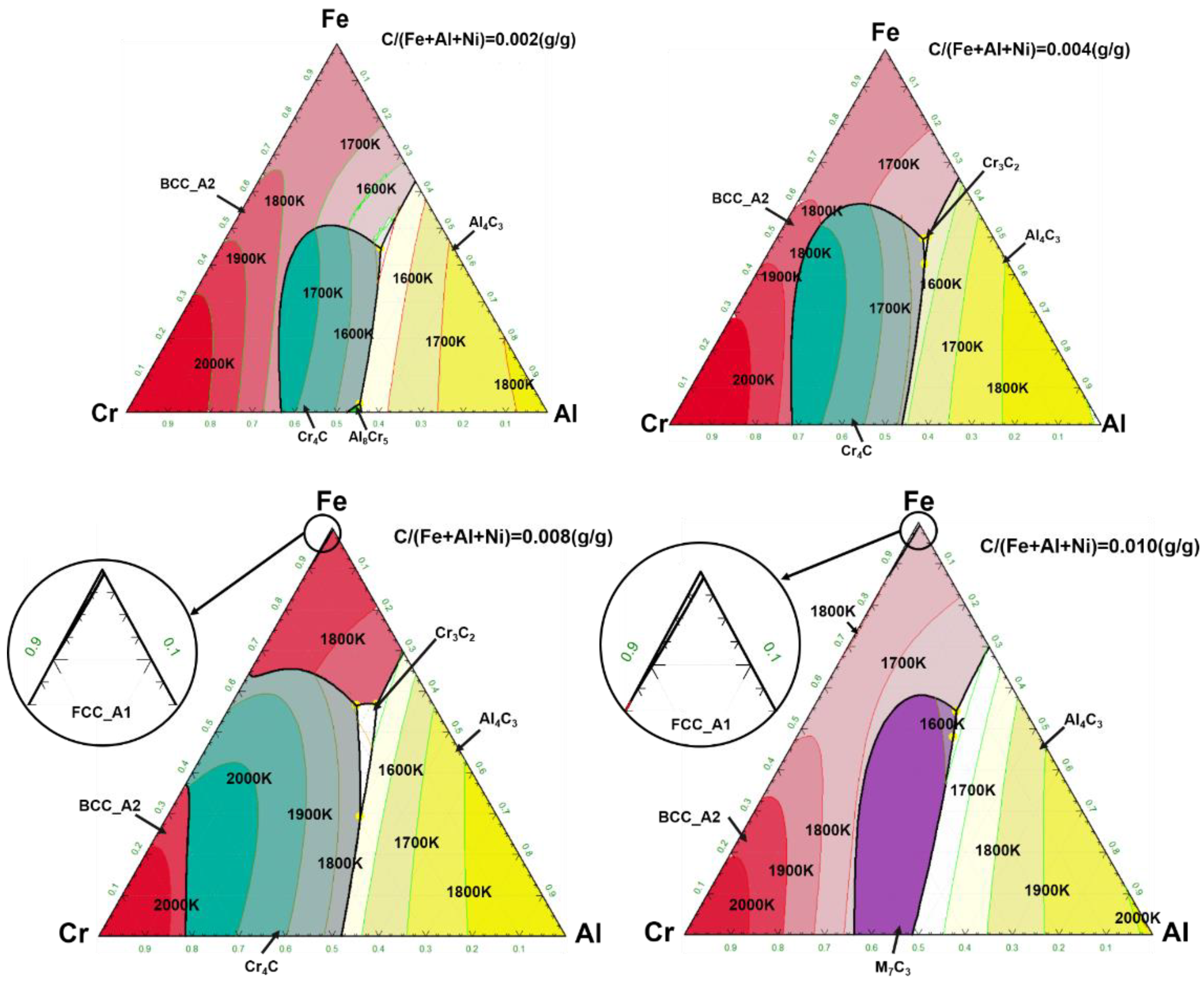

ESTIMATION OF GAMMA PHASE COMPOSITION IN NICKEL-BASE SUPERALLOYS (BASED ON GEOMETRIC ANALYSIS OF A FOUR-COMPONENT PHASE DIAGRAM) by Robert L. Dreshfield Lewis Research Center SUMMARY The nickel-rich region of the nickel-aluminum- chromium-titanium system is the basis for describing the gamma-gamma prime phase relationships in most nickel-base

Typical eutectic and a peritectic phase diagrams are illustrated in Fig. 2; these two forms describe the vast majority of phase diagrams for aluminium alloys. Fig. 2: Typical phase diagrams for aluminium alloys, illustrating a eutectic and peritectic form. Since there are no allotropic phase transformations in aluminium, much of the control

We will limit our discussion of phase diagrams of multi-component systems to binary alloys and will assume pressure to be constant at one atmosphere. Phase diagrams for materials with more than two components are complex and difficult to represent. An example of a phase diagram for a ternary alloy is shown for a fixed T and P below.

Transcribed image text: For the Aluminum (Al) Nickel (Ni) Phase Diagram Below: Welght percent nickel 1o 20 2040 SO 60 1600 3 1200 (NI) 1000 854 800 3 680452 AIN 3 L Al2N 6399 C T 600 (AD 400 10 20 30 40 so 60780 90 100 Binary Alloy Phase Diagrams 2nd Edition, edited by T.B. Massalski, ASM International 1990 page 183. a.) Fill in the rest of the diagram phase regions given the information in ...

3. Consider the aluminum - nickel (Al-Ni) phase diagram below. For this phase diagram: (a) Determine the coordinates of the composition and temperature of the invariant reactions. (Hint: there should be 6 of them) (b) Write the equations for the three-phase invariant reactions and name them. (c) Label the two-phase regions

Y. Ma and A.J. Ardell, The (γ+γ′)/γ′ Phase Boundary in the Ni-Al Phase Diagram from 600 to 1200 °C, Z. Metallkd., Vol 94 (No. 9), 2003, p 972-975 Google Scholar 2005Rag:

Phase Diagram Modelling: Nickel - Aluminum - Chromium System. ... This technical memo reviews the thermodynamic concepts upon which phase diagram models are based and presents an effective model ...

by H Okamoto · 1993 · Cited by 236 — AI-Ni (Aluminum-Nickel). H. Okamoto. Figure 1 updates the A1-Ni phase diagram in [Massalski2], which was redrawn from [91Nas]. An enlarged region of Fig. 1.3 pages

system, the phase diagram usually has the general appearance of that shown in Fig. 3. The diagram consists of two single-phase fields separated by a two-phase field. The boundary between the liquid field and the two-phase field in Fig. 3 is called the liquidus; that between the two-phase field and solid field is the solidus.

6 | GUIDE TO NICKEL ALUMINIUM BRONZE FOR ENGINEERS Broadly, the nickel aluminium bronzes can be classified as alloys containing 6-13% aluminium and up to 7% iron and 7% nickel. The more common alloys normally contain 3-6% each of these two elements. Manganese up to approximately 1.5% is also added, both as a deoxidant and a strengthening element.

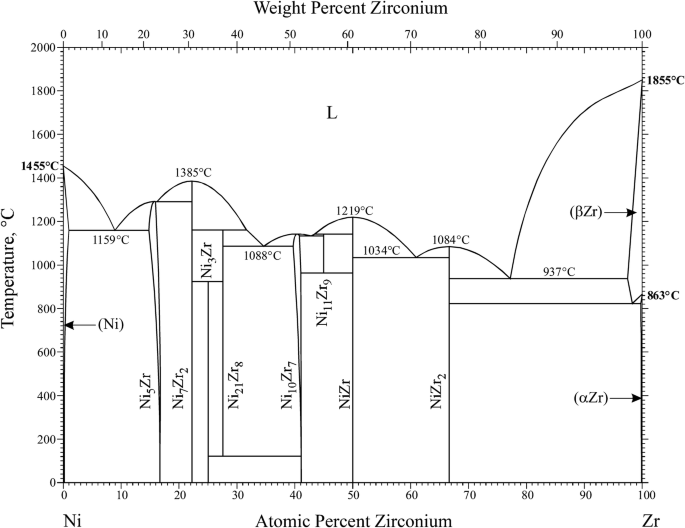

Supplemental Literature Review Of Binary Phase Diagrams Al Ni B Hf Ca Sc Cr Sc Fe Rh Hf Mn La Sb Ni Re Ni Sm Ni Zr Sb Tb And Ti Zr Springerlink

7.3. Al-Cu-Ni PHASE DIAGRAM This phase diagram is helpful in the analysis of 2618-type heat-resistant alloys and 339.0-type piston alloys that contain nickel, copper, and other alloying components (Tables 7.1 and 7.2). The ternary Al7Cu4Ni phase forms in the aluminum corner of the Al-Cu-Ni system.

The aluminum-nickel phase diagram has been provided. Identify all of the invariant points that exist in this system by the temperature and composition of the ...

Journal of Phase Equilibria - 37Ale: W.O. Alexander and N.B. Vaughan,J. Inst. Met., 61, 247-260 (1937). Google Scholar . 41Sch: J. Schramm,Z. Metallkd., 33, 347 ...

Phase Diagrams • Indicate phases as function of T, Co, and P. • For this course:-binary systems: just 2 components.-independent variables: T and Co (P = 1 atm is almost always used). • Phase Diagram for Cu-Ni system Adapted from Fig. 9.3(a), Callister 7e. (Fig. 9.3(a) is adapted from Phase Diagrams of Binary Nickel Alloys , P. Nash

forms with aluminum a series of nickel aluminides; one of them is Al 3 Ni ( in the diagram). Aluminum forms a eutectic with Al 3 Ni at 6.1 wt% nickel. The melting point of the Al-Al 3 Ni eutectic is 640 C and the volume of the Al 3 Ni phase in the eutectic is relatively large (about 9.7 wt%). Furthermore, the Al 3 Ni eutectic phase

by DF SUSAN · 2000 · Cited by 55 — Nickel-aluminum intermetallic alloys based on NiAl or Ni3Al have shown good ... coating composition and dictates, through the phase diagram, ...

Figure 1 From Mrl R 807 Survey Of Nickel Aluminium Bronze Casting Alloys On Marine Applications Semantic Scholar

Development And Application Of Phase Diagrams For Li Ion Batteries Using Calphad Approach Sciencedirect

Laser Surface Treatment To Improve The Surface Corrosion Properties Of Nickel Aluminum Bronze Sciencedirect

0 Response to "42 nickel aluminum phase diagram"

Post a Comment